Views: 0 Author: Site Editor Publish Time: 2025-08-11 Origin: Site

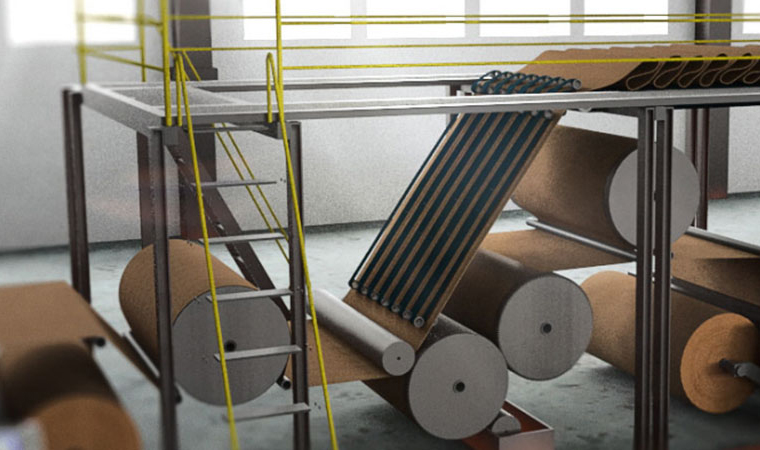

You need woven belts for your corrugated paper machine if you want strong and long-lasting performance. Woven belts are better than other conveyor belts because they can handle hard work and keep running well. IFELTEK’s Woven Belt For Corrugated Paper Machine is special because it has smart features that help it work better. The right belt stops your machine from breaking down and keeps your corrugated board making steady. Good conveyor belts help you get better results and keep the quality high every time you use them.

IFELTEK’s woven belts are very strong and last long. They have tough seams and PET fibers. They can work for up to 14,000 hours. This means you stop the machine less often.

The belts work well at high speeds. The special twill surface holds cardboard tightly. This helps move the cardboard smoothly and steadily.

These belts can handle heat up to 200°C. They let steam go through them. This helps boards dry faster. It also keeps the system working well.

Woven belts do not need much care. This saves time and keeps the conveyor running. You will need fewer repairs.

Woven belts help make better products. They keep boards flat and pressed evenly. This means less waste and better production.

You need a belt that lasts through heavy use. Woven belts from IFELTEK use PET fibers and a reinforced seam. This makes the belt strong and durable. The seam uses imported steel fasteners filled with rubber. This design helps the belt resist wear and tear. You can trust this belt to keep your conveyor belts running for a long time. The lifespan reaches up to 14,000 working hours. You will see less downtime and fewer replacements.

You want your conveyor belts to move fast and handle high loads. IFELTEK’s woven belts support high-speed operation. The twill knitting surface gives the belt a high friction coefficient. This helps the belt grip the cardboard and move it smoothly. The belt keeps its shape because of high weaving density. You get steady transport and straight running. Your system will deliver consistent results every time.

Here is a quick look at the key performance specs:

Feature | Value |

|---|---|

Thickness | 9 mm |

Width Range | 1400–3200 mm |

Tensile Strength | 65 MPa |

Coefficient of Friction | ≥ 0.4 |

Air Permeability | 2.0 m³/m²/min |

You need a belt that can handle heat and moisture in the corrugated board process. IFELTEK’s woven belts resist temperatures up to 200°C. The belt lets steam pass through with its air permeability. This helps the board dry faster and better. Your system will keep working even in tough conditions. The belt will not shrink or stretch from heat or moisture. You get reliable performance every day.

You want to spend less time fixing your conveyor belts. Woven belts from IFELTEK need little care. The strong PET fibers and reinforced seams make the belt easy to clean and hard to damage. You will see fewer breakdowns in your system. This means you can focus on making quality corrugated board, not on repairs.

Less maintenance means more uptime.

A reliable belt keeps your system running smoothly.

You need a conveyor belt system that keeps your production steady. Woven belts from IFELTEK help your system stay stable during every run. The high weaving density of the belt keeps it from stretching or shrinking. This means your conveyor belt system holds its shape and keeps the pressure even across the board. You get straight running and fewer problems with tracking. When your system stays stable, you avoid jams and keep your machines working longer. The reinforced seam on the belt adds extra strength, so your conveyor belt system can handle heavy loads without slipping or shifting.

You want your conveyor belt system to work fast and save energy. IFELTEK’s woven belt supports high-speed operation. The belt lets steam pass through easily, which helps the board dry quickly. This feature boosts the efficiency of your system. You get better product quality because the belt keeps the board flat and smooth. The air permeability of the belt helps your conveyor belt system remove moisture faster. With this belt, your system uses less energy and finishes jobs in less time. You can count on your conveyor belt system to keep up with high production demands.

Faster drying means higher efficiency.

Better grip means fewer mistakes.

You need a quiet workspace for your team. IFELTEK’s woven belt has a twill knitting surface that reduces noise during high-speed runs. The conveyor belt system stays quiet, even when you push it to top speeds. Less noise means a safer and more comfortable environment. The belt’s design helps your system run smoothly without loud vibrations or rattling. You can focus on quality and speed without the distraction of a noisy conveyor belt system.

Woven belts work inside corrugated paper machines. These belts carry cardboard sheets through each step. They move materials from the heating area to bonding and drying. IFELTEK’s belt is made for high speed. This helps your process stay smooth. The steady movement helps glue stick the paperboard layers together. The belt lets steam out, so the board dries faster. This makes your process more efficient and lowers the chance of warping.

You want every corrugated board to be high quality. The right belt helps you reach this goal. IFELTEK’s woven belt keeps the board flat and presses evenly. This makes the layers stick together well. You see fewer problems like bubbles or weak spots. The belt’s steady surface stops the board from moving. Each product looks the same. You waste less because the belt holds the board in place when cutting and stacking. Good conveyor belt use gives you better results and less waste.

Better bonding makes stronger boxes.

Even drying means fewer bad boards.

Woven belts are used in many packaging factories. These belts work great in fast corrugated board lines. They are best where you need quick drying and careful handling. IFELTEK’s belt fits new machines that need speed and quality. You use these belts to move materials in places that make shipping boxes, display boards, and special packaging. Woven belts are a good choice for many conveyor belt jobs in different factories.

You have to pick between woven belts, non-woven belts, and others for your corrugated paper machine. Woven belts are made with PET fibers that are tightly woven together. This design lets a lot of air move through the belt. More air means steam leaves faster and drying is quicker. Non-woven belts do not let as much air pass. This can make your work slower. Woven belts also last longer because they resist wearing down. The fibers stay strong even when used a lot. Other belts might break or wear out sooner. Woven belts also keep their shape for a long time. They do not stretch or shrink much. This helps the belt fit your machine well every time.

You want your machines to work well and not stop often. Woven belts hold onto the cardboard tightly and move it smoothly. The twill surface helps the belt grip better. This keeps the cardboard from slipping as it moves. You will have fewer jams and waste less material. The seam on the belt is strong and makes it last longer. You can run your machine fast without problems. The belt lets air move through, so it dries things quickly. This helps you make better products. The belt is tough, so you do not need to fix it often. Your machines keep working and you finish your jobs on time.

You need a belt that works well for today’s corrugated board making. Woven belts, like the ones from IFELTEK, are strong, steady, and work fast. The belt can handle heat, water, and heavy things easily. Your machines stay quiet and work well at high speeds. The belt is made to need less fixing and stops less often. You get better results every time you use it. Picking a woven belt means you get good quality and strong performance for your business.

You want your corrugated paper machine to work well. IFELTEK’s woven belts help your machine stay strong and last longer. These belts make your system run better and use less energy. They can handle heat, moisture, and heavy things easily. You will have fewer problems and your products will look better.

Pick woven belts for:

Steady running

Less fixing

Quiet and smooth work

Want to make your conveyor system better? Talk to IFELTEK now for help or a price.

You get a belt with high-speed support, strong PET fibers, and a reinforced seam. The twill surface reduces noise and increases grip. You see better drying and less downtime.

You can clean the belt with a soft brush or air blower. Avoid harsh chemicals. Regular checks for debris help keep the belt running smoothly. You spend less time on maintenance because the belt resists damage.

Yes, you can use the belt in environments up to 200°C. The belt keeps its shape and strength under heat. You do not need to worry about shrinking or stretching during production.