| Availability: | |

|---|---|

| Quantity: | |

IFELTEK

iFeltek

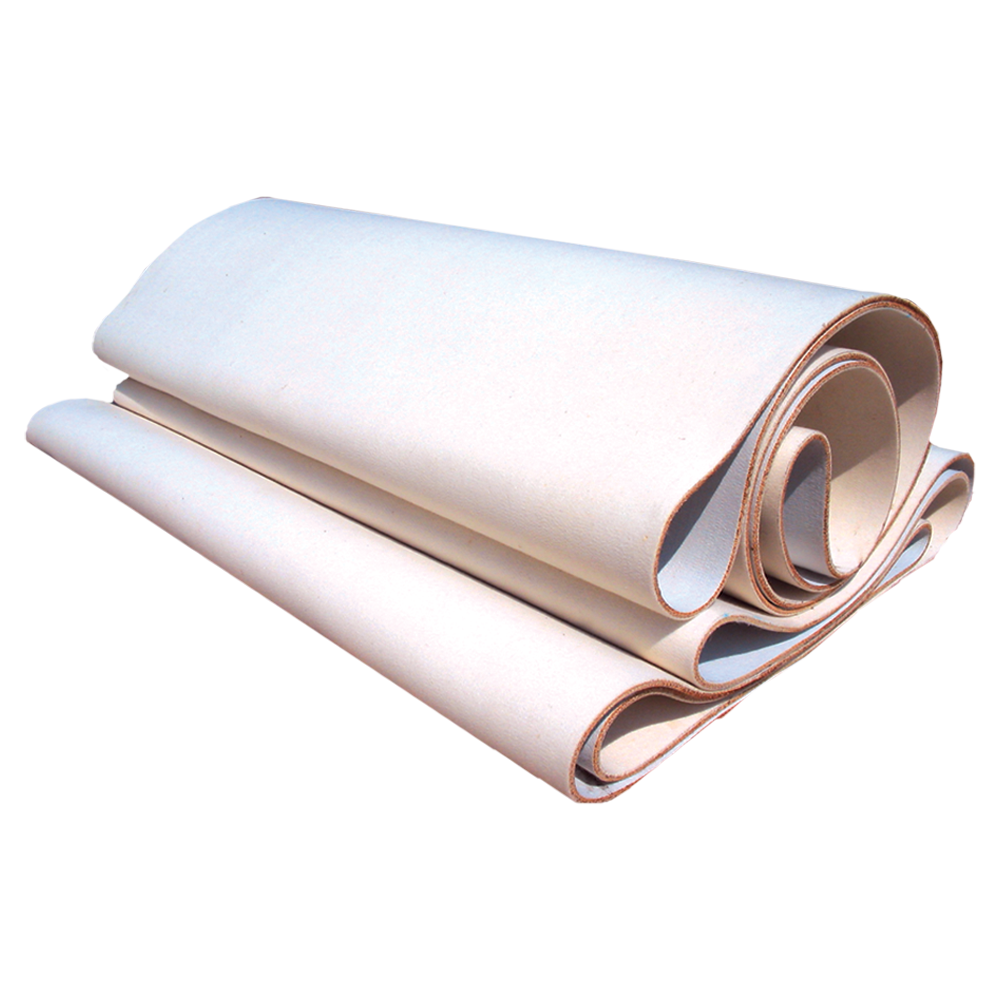

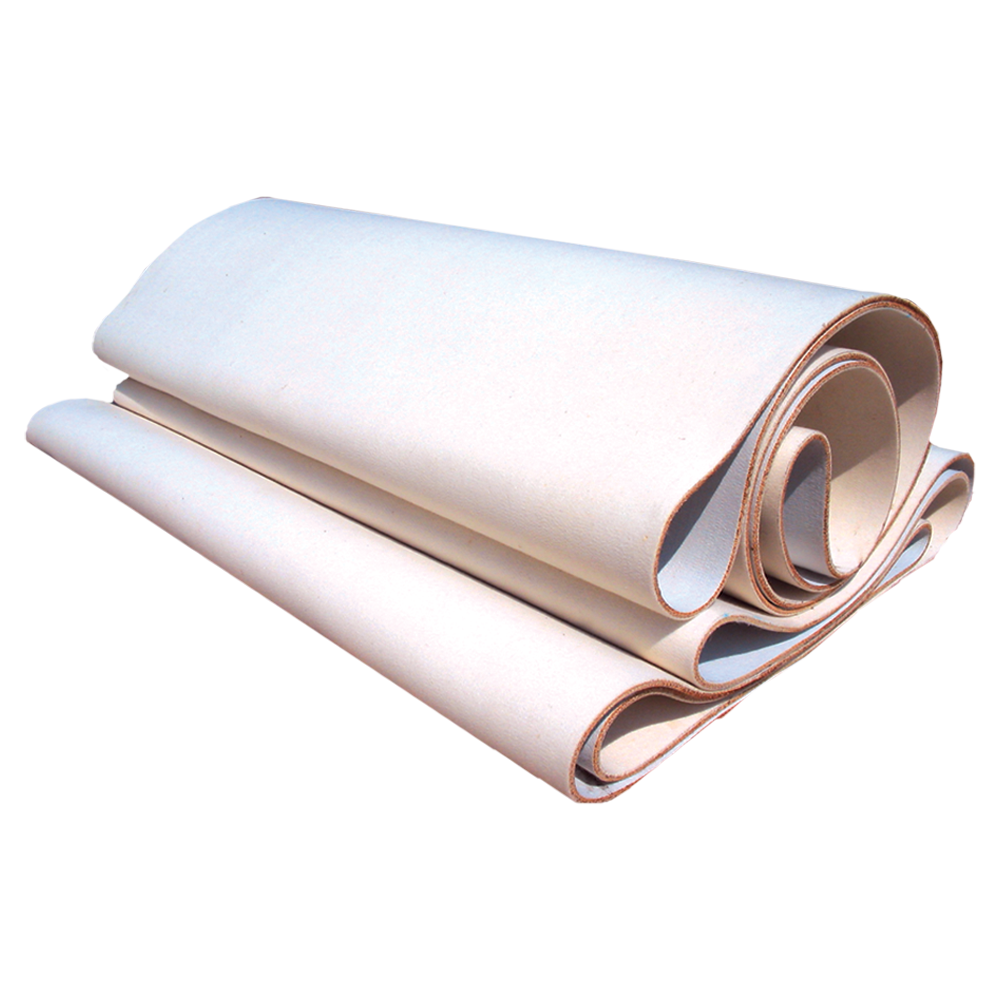

Our Customized Tannery Industrial Felt is a high-performance, anti-static material engineered exclusively for leather embossing through-feed processes in tannery production. Manufactured by iFeltek, this premium Leather Embossing Felt blends natural wool fibers with advanced synthetic materials, delivering exceptional elasticity and smoothness essential for leather ironing and embossing under high heat and pressure. Designed to fit all brands of leather ironing and embossing machines, it is the ideal core accessory for processing sheepskin and cattle hide—whether soft, thin leather or robust, heavy leather varieties.

This Through-Feed Anti-Static Felt boasts industry-leading performance attributes: a super smooth surface for seamless leather gliding, high density for uniform pressure distribution, stable dimensions to avoid deformation under high temperature, non-off tracking for consistent through-feed operation, excellent heat resistance for long-term use in high-heat processing, and a built-in anti-static composition to protect leather from static-related defects. All features work in synergy to ensure perfect embossing and ironing results for all leather types.

Tailor length, width, and thickness parameters to fit specific models of embossing or ironing machines, including non-standard equipment specifications.

Modify the blend ratio of wool and synthetic fibers based on processing requirements—optimized for soft thin leather or reinforced for heavy thick leather applications.

Adjust density parameters (based on 0.52g/cm³ standard) to enhance embossing texture definition or improve ironing smoothness, aligning with product quality goals.

Item | Specification |

Brand | iFeltek |

Model | IFELTEK |

Material | Wool + Synthetic Fiber |

Density | 0.52g/cm³ (customizable) |

Product Condition | New |

Delivery Time | 20-30 days after order confirmation |

Place of Origin | Anhui, Hefei, China |

Core Function | Leather ironing, embossing through-feed processing; anti-static protection |

Compatibility | All brands of tannery ironing/embossing machines |

Specialized for continuous embossing of sheepskin and cattle hide, ensuring consistent pattern transfer and texture depth across large production batches.

Ideal for high-precision ironing of all leather types, refining surface smoothness and eliminating wrinkles without damaging leather fibers.

Suitable for mass production of leather products requiring intricate patterns, supporting tannery factories in meeting high-volume market demand.

Serves as a core accessory for industrial leather embossing/ironing machines, supporting equipment suppliers and tannery production lines worldwide.

The wool-synthetic fiber combination leverages wool’s natural elasticity and smoothness for gentle yet effective leather contact, while synthetic materials enhance durability and heat resistance—extending service life under harsh processing conditions.

No need for production line modifications; the felt is engineered to fit all brands and models of tannery ironing and embossing machines, reducing equipment adaptation costs.

Exclusive anti-static composition prevents static electricity accumulation during through-feed processing, avoiding leather surface scratches, dust adsorption, and other quality defects.

Maintains dimension stability and non-off tracking operation under high heat (typical processing temperatures) and intense pressure, ensuring consistent production quality and minimizing equipment adjustment downtime.

Optimized design adapts seamlessly to soft thin leather and heavy thick leather processing, meeting the diverse production needs of tannery enterprises for different product lines.

Our Through-Feed Anti-Static Felt is fully compatible with all brands and models of tannery ironing and embossing machines on the market. For non-standard machines, we provide dimension customization to ensure a perfect fit for your equipment.

For both standard and customized orders, we guarantee delivery within 20-30 days after order confirmation. Bulk orders receive priority production scheduling to align with your production line timelines.

Yes. The high-density wool-synthetic blend and heat-resistant design enable 24/7 continuous through-feed processing. The felt features low wear and no fiber shedding, preventing leather contamination and ensuring consistent performance.

If you are looking for a high-performance Leather Embossing Felt to elevate your tannery production line, our professional team offers one-stop customization and consulting services tailored to your needs!

Our Customized Tannery Industrial Felt is a high-performance, anti-static material engineered exclusively for leather embossing through-feed processes in tannery production. Manufactured by iFeltek, this premium Leather Embossing Felt blends natural wool fibers with advanced synthetic materials, delivering exceptional elasticity and smoothness essential for leather ironing and embossing under high heat and pressure. Designed to fit all brands of leather ironing and embossing machines, it is the ideal core accessory for processing sheepskin and cattle hide—whether soft, thin leather or robust, heavy leather varieties.

This Through-Feed Anti-Static Felt boasts industry-leading performance attributes: a super smooth surface for seamless leather gliding, high density for uniform pressure distribution, stable dimensions to avoid deformation under high temperature, non-off tracking for consistent through-feed operation, excellent heat resistance for long-term use in high-heat processing, and a built-in anti-static composition to protect leather from static-related defects. All features work in synergy to ensure perfect embossing and ironing results for all leather types.

Tailor length, width, and thickness parameters to fit specific models of embossing or ironing machines, including non-standard equipment specifications.

Modify the blend ratio of wool and synthetic fibers based on processing requirements—optimized for soft thin leather or reinforced for heavy thick leather applications.

Adjust density parameters (based on 0.52g/cm³ standard) to enhance embossing texture definition or improve ironing smoothness, aligning with product quality goals.

Item | Specification |

Brand | iFeltek |

Model | IFELTEK |

Material | Wool + Synthetic Fiber |

Density | 0.52g/cm³ (customizable) |

Product Condition | New |

Delivery Time | 20-30 days after order confirmation |

Place of Origin | Anhui, Hefei, China |

Core Function | Leather ironing, embossing through-feed processing; anti-static protection |

Compatibility | All brands of tannery ironing/embossing machines |

Specialized for continuous embossing of sheepskin and cattle hide, ensuring consistent pattern transfer and texture depth across large production batches.

Ideal for high-precision ironing of all leather types, refining surface smoothness and eliminating wrinkles without damaging leather fibers.

Suitable for mass production of leather products requiring intricate patterns, supporting tannery factories in meeting high-volume market demand.

Serves as a core accessory for industrial leather embossing/ironing machines, supporting equipment suppliers and tannery production lines worldwide.

The wool-synthetic fiber combination leverages wool’s natural elasticity and smoothness for gentle yet effective leather contact, while synthetic materials enhance durability and heat resistance—extending service life under harsh processing conditions.

No need for production line modifications; the felt is engineered to fit all brands and models of tannery ironing and embossing machines, reducing equipment adaptation costs.

Exclusive anti-static composition prevents static electricity accumulation during through-feed processing, avoiding leather surface scratches, dust adsorption, and other quality defects.

Maintains dimension stability and non-off tracking operation under high heat (typical processing temperatures) and intense pressure, ensuring consistent production quality and minimizing equipment adjustment downtime.

Optimized design adapts seamlessly to soft thin leather and heavy thick leather processing, meeting the diverse production needs of tannery enterprises for different product lines.

Our Through-Feed Anti-Static Felt is fully compatible with all brands and models of tannery ironing and embossing machines on the market. For non-standard machines, we provide dimension customization to ensure a perfect fit for your equipment.

For both standard and customized orders, we guarantee delivery within 20-30 days after order confirmation. Bulk orders receive priority production scheduling to align with your production line timelines.

Yes. The high-density wool-synthetic blend and heat-resistant design enable 24/7 continuous through-feed processing. The felt features low wear and no fiber shedding, preventing leather contamination and ensuring consistent performance.

If you are looking for a high-performance Leather Embossing Felt to elevate your tannery production line, our professional team offers one-stop customization and consulting services tailored to your needs!