| Availability: | |

|---|---|

| Quantity: | |

IFELTEK

iFeltek

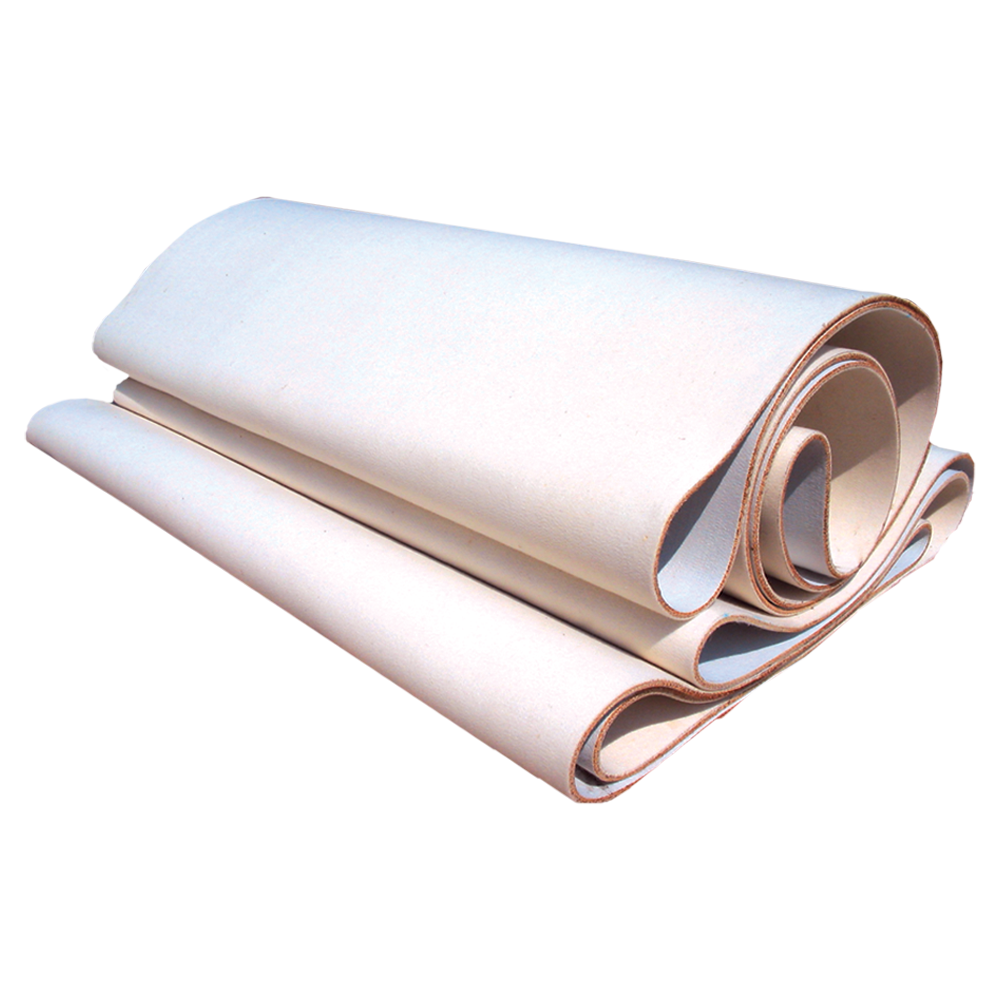

Our Customized Industrial Felt is a high-performance, anti-static material engineered exclusively for tannery leather ironing and through-feed embossing processes, crafted by iFeltek to meet the rigorous demands of leather processing. Blending premium wool and synthetic fibers, this Tannery Leather Ironing Felt delivers exceptional smoothness and heat resistance, enabling leather hides to glide seamlessly through high-pressure, high-temperature ironing and embossing cylinders. It is universally compatible with all brands of leather ironing and embossing machines, ideal for processing both soft/thin and robust/heavy sheepskin and cattle hide. As a core component for tannery post-finishing, this anti-static through-feed felt ensures leather achieves a refined, consistent aesthetic and texture, with stable dimensional performance to avoid off-tracking during continuous production.

This Anti-Static Through-Feed Felt integrates industry-leading performance attributes: smooth surface for scratch-free leather processing, high density for uniform pressure distribution, stable dimension for long-term continuous use, non-off tracking for automated production lines, excellent heat resistance for high-temperature ironing, and anti-static composition to prevent dust adhesion on leather surfaces.

We offer fully customized solutions for our Customized Industrial Felt, including personalized adjustments to size, thickness, and density based on your tannery’s specific machine models and leather processing requirements. Whether for small-scale precision embossing or large-volume through-feed ironing, our customization service ensures the felt perfectly matches your production workflow.

Parameter | Detail |

Model | IFELTEK |

Brand | iFeltek |

Material | Wool + Synthetic Fiber Blend |

Density | 0.52g/cm³ |

Condition | Brand New |

Delivery Time | 20-30 days |

Place of Origin | China (Anhui Hefei) |

Core Function | Specialized for tannery leather ironing/embossing machines |

Core Performance | Smooth surface, high density, anti-static, heat resistance |

Our Tannery Leather Ironing Felt is designed for tannery post-finishing processes, with primary applications in:

Through-feed ironing of sheepskin and cattle hide (both soft/thin and heavy leather varieties);

Intricate embossing and texture creation on leather surfaces via high-pressure/high-temperature cylinder machines;

Automated tannery production lines requiring non-off tracking, long-lasting felt materials;

All brands of professional leather ironing and embossing equipment in the leather processing industry.

Premium Material Blend: Wool fibers deliver unrivaled elasticity and smoothness, while synthetic fibers enhance durability and heat resistance, ensuring optimal performance under high-pressure/temperature conditions;

Universal Compatibility: No need to replace existing tannery equipment—our felt is compatible with all mainstream ironing and embossing machine brands, reducing production reconfiguration costs;

Stable Production Performance: Non-off tracking and dimensionally stable design minimize production downtime and leather waste caused by felt displacement;

Anti-Static & Scratch-Free: Anti-static composition prevents dust and static adhesion, while the ultra-smooth surface ensures no scratches on delicate leather hides;

Customizable Design: Tailored to your production needs, our customization service ensures the felt aligns with your specific processing requirements for different leather types.

Our felt uses a wool-synthetic fiber blend with high heat resistance, which can withstand the high-temperature and high-pressure environment of leather ironing machines without deformation, ensuring consistent production quality.

Yes. We provide full customization for size, density, and thickness according to your machine’s technical parameters and leather processing needs, ensuring a perfect fit for non-standard equipment.

The standard delivery time is 20-30 days for all customized orders, with flexible scheduling available for bulk or urgent tannery production needs.

If you are looking for a high-performance, anti-static Customized Industrial Felt for your tannery’s through-feed ironing and embossing processes, our professional team is ready to provide tailored solutions for your production needs.

Our Customized Industrial Felt is a high-performance, anti-static material engineered exclusively for tannery leather ironing and through-feed embossing processes, crafted by iFeltek to meet the rigorous demands of leather processing. Blending premium wool and synthetic fibers, this Tannery Leather Ironing Felt delivers exceptional smoothness and heat resistance, enabling leather hides to glide seamlessly through high-pressure, high-temperature ironing and embossing cylinders. It is universally compatible with all brands of leather ironing and embossing machines, ideal for processing both soft/thin and robust/heavy sheepskin and cattle hide. As a core component for tannery post-finishing, this anti-static through-feed felt ensures leather achieves a refined, consistent aesthetic and texture, with stable dimensional performance to avoid off-tracking during continuous production.

This Anti-Static Through-Feed Felt integrates industry-leading performance attributes: smooth surface for scratch-free leather processing, high density for uniform pressure distribution, stable dimension for long-term continuous use, non-off tracking for automated production lines, excellent heat resistance for high-temperature ironing, and anti-static composition to prevent dust adhesion on leather surfaces.

We offer fully customized solutions for our Customized Industrial Felt, including personalized adjustments to size, thickness, and density based on your tannery’s specific machine models and leather processing requirements. Whether for small-scale precision embossing or large-volume through-feed ironing, our customization service ensures the felt perfectly matches your production workflow.

Parameter | Detail |

Model | IFELTEK |

Brand | iFeltek |

Material | Wool + Synthetic Fiber Blend |

Density | 0.52g/cm³ |

Condition | Brand New |

Delivery Time | 20-30 days |

Place of Origin | China (Anhui Hefei) |

Core Function | Specialized for tannery leather ironing/embossing machines |

Core Performance | Smooth surface, high density, anti-static, heat resistance |

Our Tannery Leather Ironing Felt is designed for tannery post-finishing processes, with primary applications in:

Through-feed ironing of sheepskin and cattle hide (both soft/thin and heavy leather varieties);

Intricate embossing and texture creation on leather surfaces via high-pressure/high-temperature cylinder machines;

Automated tannery production lines requiring non-off tracking, long-lasting felt materials;

All brands of professional leather ironing and embossing equipment in the leather processing industry.

Premium Material Blend: Wool fibers deliver unrivaled elasticity and smoothness, while synthetic fibers enhance durability and heat resistance, ensuring optimal performance under high-pressure/temperature conditions;

Universal Compatibility: No need to replace existing tannery equipment—our felt is compatible with all mainstream ironing and embossing machine brands, reducing production reconfiguration costs;

Stable Production Performance: Non-off tracking and dimensionally stable design minimize production downtime and leather waste caused by felt displacement;

Anti-Static & Scratch-Free: Anti-static composition prevents dust and static adhesion, while the ultra-smooth surface ensures no scratches on delicate leather hides;

Customizable Design: Tailored to your production needs, our customization service ensures the felt aligns with your specific processing requirements for different leather types.

Our felt uses a wool-synthetic fiber blend with high heat resistance, which can withstand the high-temperature and high-pressure environment of leather ironing machines without deformation, ensuring consistent production quality.

Yes. We provide full customization for size, density, and thickness according to your machine’s technical parameters and leather processing needs, ensuring a perfect fit for non-standard equipment.

The standard delivery time is 20-30 days for all customized orders, with flexible scheduling available for bulk or urgent tannery production needs.

If you are looking for a high-performance, anti-static Customized Industrial Felt for your tannery’s through-feed ironing and embossing processes, our professional team is ready to provide tailored solutions for your production needs.