| Availability: | |

|---|---|

| Quantity: | |

IFELTEK

iFeltek

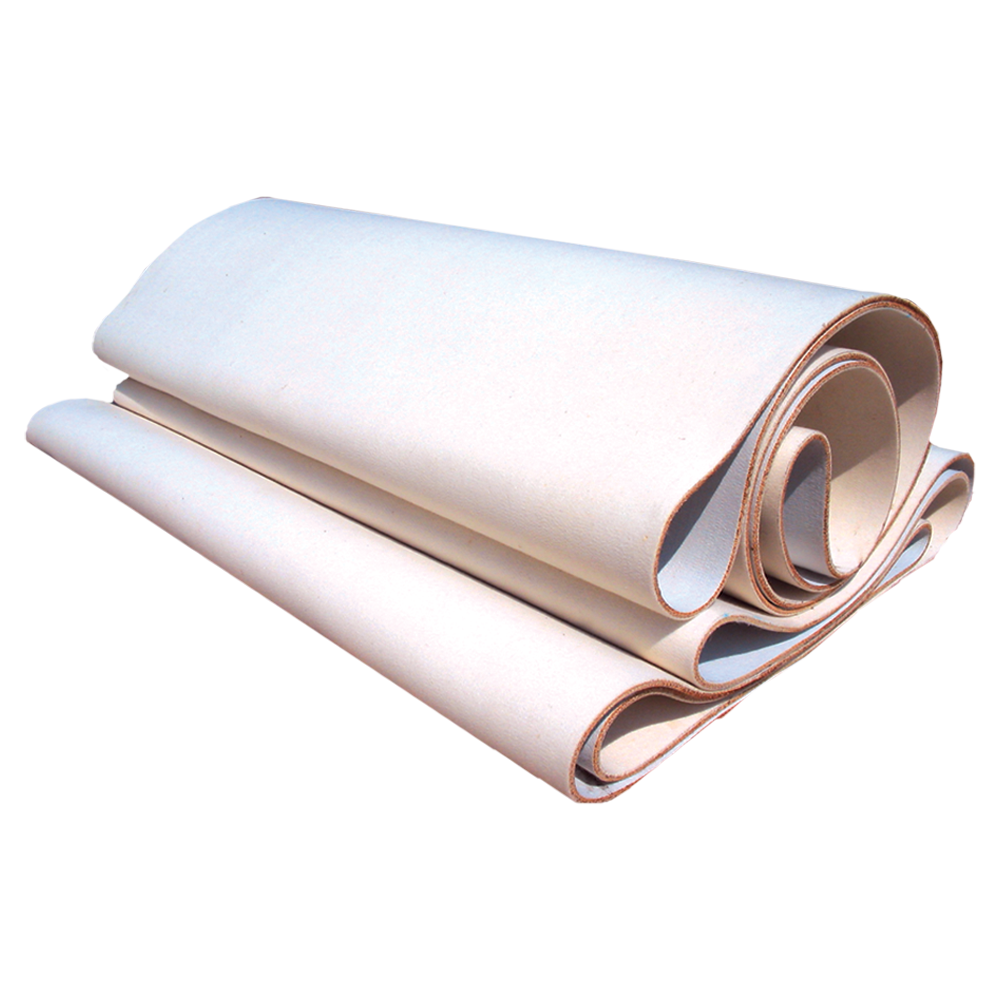

Our Customized Anti-Static Industrial Felt is a high-performance premium material engineered exclusively for leather through-feed processes in tanneries, also known as embossing felt or leather felt. Crafted by iFeltek, this industrial felt is the core consumable for leather ironing and embossing machines, designed to optimize the entire through-feed processing workflow. Made from a high-quality blend of wool + synthetic fibers, it leverages the natural elasticity and smoothness of wool fibers, combined with enhanced anti-static and durable synthetic fiber properties, to ensure leather hides glide seamlessly through high-pressure, high-heat processing.

Anti-static performance: The specialized fiber blend effectively dissipates static electricity, avoiding leather surface damage and material adhesion caused by static during high-speed through-feed processing.

Superior physical traits: Boasts a smooth surface, high density (0.52g/cm³), stable dimension and non-off tracking design, ensuring consistent contact with leather and machines, and no deviation in long-term continuous operation.

Excellent heat resistance: Adapts to the high-temperature environment of leather ironing and embossing processes, maintaining structural stability and performance without deformation or aging.

Wool fiber advantages: Retains the natural elasticity and smoothness of wool, reducing friction with leather hides and preventing scratches on delicate leather surfaces.

We offer fully customized Anti-Static Industrial Felt solutions to match the unique requirements of different tannery through-feed processes: customizable dimensions (length, width, thickness) to fit various models of ironing and embossing machines; adjustable anti-static grade for leather types with different static sensitivity; and tailored density variations for light and heavy leather processing scenarios. All customizations are engineered to ensure perfect compatibility with your production equipment and leather processing needs.

Item | Specification |

Material | Wool + Synthetic Fibers |

Density | 0.52g/cm³ |

Condition | New, factory direct supply |

Delivery Time | Within 20-30 days for customized orders |

Place of Origin | Hefei, Anhui, China |

Core Function | Specialized for leather ironing/embossing machines in through-feed processes |

Key Performance Traits | Smooth surface, High density, Stable dimension, Non-off tracking, Good heat resistance |

Serves as the core padding and conveying material for leather ironing machines, ensuring leather hides are ironed evenly under high pressure and temperature. The smooth surface and stable dimension of the felt eliminate leather surface creases and unevenness, creating a flat, refined base surface for subsequent processing—suitable for all soft, thin and heavy leather types.

Acts as the matching material for embossing machines, enabling the creation of intricate and clear patterns/textures on leather surfaces. The high density and heat resistance of the felt ensure the embossing effect is consistent and durable, without pattern distortion during the through-feed process.

This product is applicable to all types of tannery through-feed processing equipment, and is the ideal choice for sheepskin, cattle hide and other leather material processing.

Our felt is a specialized blend of wool and synthetic fibers, combining wool’s elasticity/smoothness with synthetic fibers’ anti-static/heat-resistant properties. It addresses core pain points of through-feed processes (static, deviation, surface damage) and is compatible with all brand machines, ensuring optimal leather processing results.

Yes, we support customized production for all order volumes, including small batches. We can tailor dimensions, anti-static grade and density according to your specific production equipment and leather processing needs.

Thanks to its high density and durable fiber blend, the felt has an extended service life in 24/7 continuous tannery production, and maintains stable performance without easy wear, deformation or off tracking.

Are you looking for a high-performance Anti-Static Industrial Felt to optimize your tannery leather through-feed processes? Our customized solutions from iFeltek are tailored to your exact production needs!

Direct Consultation: Call our professional sales team at 0086-551-62870071 (Monday-Friday, 8:30 AM - 5:30 PM CST)

Email Inquiry: Send your customization requirements, equipment models and leather processing details to info@ifeltek.com—we will reply with a detailed quotation and solution within 24 working hours

Quick Action: Click Inquire to submit your order request, or Add to Basket for bulk purchase consultation

Our Customized Anti-Static Industrial Felt is a high-performance premium material engineered exclusively for leather through-feed processes in tanneries, also known as embossing felt or leather felt. Crafted by iFeltek, this industrial felt is the core consumable for leather ironing and embossing machines, designed to optimize the entire through-feed processing workflow. Made from a high-quality blend of wool + synthetic fibers, it leverages the natural elasticity and smoothness of wool fibers, combined with enhanced anti-static and durable synthetic fiber properties, to ensure leather hides glide seamlessly through high-pressure, high-heat processing.

Anti-static performance: The specialized fiber blend effectively dissipates static electricity, avoiding leather surface damage and material adhesion caused by static during high-speed through-feed processing.

Superior physical traits: Boasts a smooth surface, high density (0.52g/cm³), stable dimension and non-off tracking design, ensuring consistent contact with leather and machines, and no deviation in long-term continuous operation.

Excellent heat resistance: Adapts to the high-temperature environment of leather ironing and embossing processes, maintaining structural stability and performance without deformation or aging.

Wool fiber advantages: Retains the natural elasticity and smoothness of wool, reducing friction with leather hides and preventing scratches on delicate leather surfaces.

We offer fully customized Anti-Static Industrial Felt solutions to match the unique requirements of different tannery through-feed processes: customizable dimensions (length, width, thickness) to fit various models of ironing and embossing machines; adjustable anti-static grade for leather types with different static sensitivity; and tailored density variations for light and heavy leather processing scenarios. All customizations are engineered to ensure perfect compatibility with your production equipment and leather processing needs.

Item | Specification |

Material | Wool + Synthetic Fibers |

Density | 0.52g/cm³ |

Condition | New, factory direct supply |

Delivery Time | Within 20-30 days for customized orders |

Place of Origin | Hefei, Anhui, China |

Core Function | Specialized for leather ironing/embossing machines in through-feed processes |

Key Performance Traits | Smooth surface, High density, Stable dimension, Non-off tracking, Good heat resistance |

Serves as the core padding and conveying material for leather ironing machines, ensuring leather hides are ironed evenly under high pressure and temperature. The smooth surface and stable dimension of the felt eliminate leather surface creases and unevenness, creating a flat, refined base surface for subsequent processing—suitable for all soft, thin and heavy leather types.

Acts as the matching material for embossing machines, enabling the creation of intricate and clear patterns/textures on leather surfaces. The high density and heat resistance of the felt ensure the embossing effect is consistent and durable, without pattern distortion during the through-feed process.

This product is applicable to all types of tannery through-feed processing equipment, and is the ideal choice for sheepskin, cattle hide and other leather material processing.

Our felt is a specialized blend of wool and synthetic fibers, combining wool’s elasticity/smoothness with synthetic fibers’ anti-static/heat-resistant properties. It addresses core pain points of through-feed processes (static, deviation, surface damage) and is compatible with all brand machines, ensuring optimal leather processing results.

Yes, we support customized production for all order volumes, including small batches. We can tailor dimensions, anti-static grade and density according to your specific production equipment and leather processing needs.

Thanks to its high density and durable fiber blend, the felt has an extended service life in 24/7 continuous tannery production, and maintains stable performance without easy wear, deformation or off tracking.

Are you looking for a high-performance Anti-Static Industrial Felt to optimize your tannery leather through-feed processes? Our customized solutions from iFeltek are tailored to your exact production needs!

Direct Consultation: Call our professional sales team at 0086-551-62870071 (Monday-Friday, 8:30 AM - 5:30 PM CST)

Email Inquiry: Send your customization requirements, equipment models and leather processing details to info@ifeltek.com—we will reply with a detailed quotation and solution within 24 working hours

Quick Action: Click Inquire to submit your order request, or Add to Basket for bulk purchase consultation