| Availability: | |

|---|---|

| Quantity: | |

IFELTEK

iFeltek

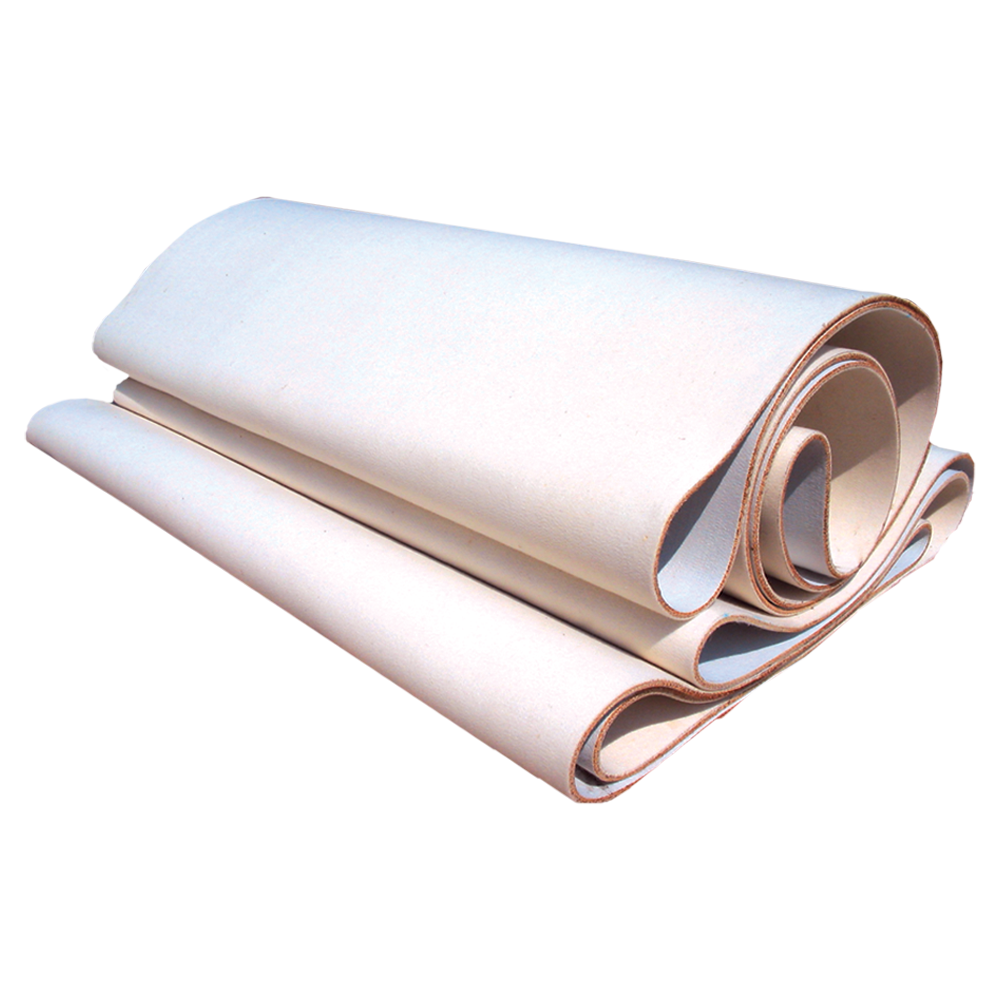

The Anti-Static Through-Feed Felt for Leather Embossing (also named Leather Embossing Felt/Tannery Ironing Felt) is a high-performance industrial felt product independently developed by iFeltek, a professional manufacturer of industrial felt and conveyor belt solutions. Crafted from a premium blend of wool + synthetic fiber, this felt is engineered for the ironing and embossing through-feed process in the tannery industry. It acts as the core conveying and forming material for leather embossing machines, carrying hide through high-pressure and high-temperature cylinder processing to create the desired texture, touch and finish for sheepskin, cattle hide and other leather materials. With anti-static performance and excellent physical properties, it is compatible with all brands of leather ironing and embossing machines, and can be adapted to processing demands of soft/thin leather and heavy leather, from basic ironing to deep embossing, making it an essential consumable for the tannery after-finishing process.

Smooth surface: Ensures no scratch on leather surface during embossing and ironing, maintaining perfect leather finish

High density: Provides stable support under high pressure, avoiding deformation of leather patterns

Stable dimension: Resists shrinkage and expansion under high temperature, ensuring consistent processing accuracy

Non-off tracking: Realizes smooth conveying on through-feed equipment, reducing machine downtime

Good heat resistance: Adapts to the high-temperature working environment of leather embossing machines

Anti-static property: Prevents static electricity accumulation, avoiding dust adsorption and leather surface damage

Customized specifications for all brands of leather ironing/embossing machines

Tailored felt performance for different processes: ordinary leather ironing, deep pattern embossing

Size customization for soft/thin leather and heavy leather processing requirements

Item | Specification |

Brand | iFeltek |

Model | IFELTEK |

Material | Wool + Synthetic Fiber |

Density | 0.52g/cm³ |

Product Condition | New |

Place of Origin | Anhui, China |

Delivery Time | Within 20-30 days |

Core Function | Applied to leather ironing/embossing machines for tannery processing |

Main Performance | Smooth surface, high density, anti-static, heat resistant |

This Anti-Static Through-Feed Felt is mainly applied to the tannery industry, the core application scenarios include:

Through-feed ironing process of sheepskin, cattle hide and other leather materials in tanneries

Deep embossing and pattern forming process of soft/thin leather and heavy leather

Matching with all mainstream brands of leather embossing machines and leather ironing machines in the market

Continuous through-feed processing line of leather after-finishing, realizing integrated ironing and embossing

Premium raw material performance: Utilizes the elastic and smooth characteristics of wool fiber, combined with synthetic fiber to enhance durability and anti-static effect, perfectly adapting to high-pressure and high-temperature leather processing

Full process adaptability: Covers all leather processing links from basic ironing to deep embossing, and is suitable for different types of leather, meeting the diversified production needs of tanneries

Universal equipment compatibility: No need to modify the original machine, directly matching all brands of leather ironing and embossing machines, reducing the replacement cost of accessories

Stable and reliable use: Non-off tracking, dimensionally stable and heat resistant, ensuring long-term continuous operation of the production line and improving tannery production efficiency

Standardized quality control: All products are new and manufactured in accordance with strict industrial standards, with consistent quality and stable processing effect

It is specially designed for sheepskin and cattle hide processing, and is fully applicable to soft/thin leather and heavy leather, supporting both ordinary ironing and deep embossing processes of various leather materials.

Yes, we provide full customization services for all brands of leather ironing and embossing machines in the market. You only need to provide the machine model and processing requirements, and we will customize the matching felt specifications for you.

For all regular and customized orders, the standard delivery time is within 20-30 days from the date of order confirmation, and we will ensure on-time delivery with stable product quality.

The Anti-Static Through-Feed Felt for Leather Embossing (also named Leather Embossing Felt/Tannery Ironing Felt) is a high-performance industrial felt product independently developed by iFeltek, a professional manufacturer of industrial felt and conveyor belt solutions. Crafted from a premium blend of wool + synthetic fiber, this felt is engineered for the ironing and embossing through-feed process in the tannery industry. It acts as the core conveying and forming material for leather embossing machines, carrying hide through high-pressure and high-temperature cylinder processing to create the desired texture, touch and finish for sheepskin, cattle hide and other leather materials. With anti-static performance and excellent physical properties, it is compatible with all brands of leather ironing and embossing machines, and can be adapted to processing demands of soft/thin leather and heavy leather, from basic ironing to deep embossing, making it an essential consumable for the tannery after-finishing process.

Smooth surface: Ensures no scratch on leather surface during embossing and ironing, maintaining perfect leather finish

High density: Provides stable support under high pressure, avoiding deformation of leather patterns

Stable dimension: Resists shrinkage and expansion under high temperature, ensuring consistent processing accuracy

Non-off tracking: Realizes smooth conveying on through-feed equipment, reducing machine downtime

Good heat resistance: Adapts to the high-temperature working environment of leather embossing machines

Anti-static property: Prevents static electricity accumulation, avoiding dust adsorption and leather surface damage

Customized specifications for all brands of leather ironing/embossing machines

Tailored felt performance for different processes: ordinary leather ironing, deep pattern embossing

Size customization for soft/thin leather and heavy leather processing requirements

Item | Specification |

Brand | iFeltek |

Model | IFELTEK |

Material | Wool + Synthetic Fiber |

Density | 0.52g/cm³ |

Product Condition | New |

Place of Origin | Anhui, China |

Delivery Time | Within 20-30 days |

Core Function | Applied to leather ironing/embossing machines for tannery processing |

Main Performance | Smooth surface, high density, anti-static, heat resistant |

This Anti-Static Through-Feed Felt is mainly applied to the tannery industry, the core application scenarios include:

Through-feed ironing process of sheepskin, cattle hide and other leather materials in tanneries

Deep embossing and pattern forming process of soft/thin leather and heavy leather

Matching with all mainstream brands of leather embossing machines and leather ironing machines in the market

Continuous through-feed processing line of leather after-finishing, realizing integrated ironing and embossing

Premium raw material performance: Utilizes the elastic and smooth characteristics of wool fiber, combined with synthetic fiber to enhance durability and anti-static effect, perfectly adapting to high-pressure and high-temperature leather processing

Full process adaptability: Covers all leather processing links from basic ironing to deep embossing, and is suitable for different types of leather, meeting the diversified production needs of tanneries

Universal equipment compatibility: No need to modify the original machine, directly matching all brands of leather ironing and embossing machines, reducing the replacement cost of accessories

Stable and reliable use: Non-off tracking, dimensionally stable and heat resistant, ensuring long-term continuous operation of the production line and improving tannery production efficiency

Standardized quality control: All products are new and manufactured in accordance with strict industrial standards, with consistent quality and stable processing effect

It is specially designed for sheepskin and cattle hide processing, and is fully applicable to soft/thin leather and heavy leather, supporting both ordinary ironing and deep embossing processes of various leather materials.

Yes, we provide full customization services for all brands of leather ironing and embossing machines in the market. You only need to provide the machine model and processing requirements, and we will customize the matching felt specifications for you.

For all regular and customized orders, the standard delivery time is within 20-30 days from the date of order confirmation, and we will ensure on-time delivery with stable product quality.